Welcome to Roger Russell's

History Page About

The Clocks of Leendert Prins

Including Etalage Reclame

Corp., Sonic Industries Inc., Monitor Equipment Corp.,

MagiClock, Boots Boy, Rex Cole, LeCoultre and Smiths

Copyright

1996-2005 by Roger Russell

All rights reserved

No portion of this site may be reproduced in whole or in part

for any reason without written permission of the author.

These clocks, including some of the Jefferson Electric clocks, are based on patents awarded in the 1940's to Leendert Prins. The patents are No. 2,248,195, RE22640, and No. 2,642,713. The name Etalage and Etalage Reclame is on a few of the clocks. Etalage Reclame is French and means something like dramatically effective display.

![]()

What's on this Page?

|

Magic Crystal

Clock |

![]()

The patent number 2,642,713 can be found on several Jefferson

clocks. The patent was awarded to Leendert Prins. Jefferson

bought the patent rights. The clock described in the patent was made by the Etalage

Reclame Corporation.

The patent number 2,642,713 can be found on several Jefferson

clocks. The patent was awarded to Leendert Prins. Jefferson

bought the patent rights. The clock described in the patent was made by the Etalage

Reclame Corporation.

Application number 645,998 was filed on February 7, 1946 but it was abandoned. Application for a new patent,

serial number 101,510, was made in France on September 10, 1948 and in the United

States on June 27, 1949. On June 23, 1953 the patent was issued to Leendert Prins.

Application number 645,998 was filed on February 7, 1946 but it was abandoned. Application for a new patent,

serial number 101,510, was made in France on September 10, 1948 and in the United

States on June 27, 1949. On June 23, 1953 the patent was issued to Leendert Prins.

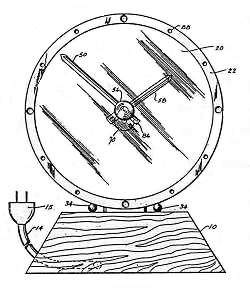

The patent describes the clock in great detail with 3 pages of illustrations. The round dial, glass and hand assembly is mounted on a wooden base. The motor is mounted vertically and protrudes from the rear of the clock. It has advantages over the earlier Prins patent.

It incorporates a single transparent disc with a

minute hand frictionally attached to it that drives the hour hand by gears and

a weight. It is improved over the two-disc clock for ease of setting the hours

and minutes independently. The patent further describes: "....the single

disk itself may be omitted and the minute hand connected to the rotating gear

which is mounted in the clock frame and masked from view thereby.....and yet

the illusion of a mysterious drive is retained or even heightened...." The

inventor's address is Bilthoven, Netherlands.

It incorporates a single transparent disc with a

minute hand frictionally attached to it that drives the hour hand by gears and

a weight. It is improved over the two-disc clock for ease of setting the hours

and minutes independently. The patent further describes: "....the single

disk itself may be omitted and the minute hand connected to the rotating gear

which is mounted in the clock frame and masked from view thereby.....and yet

the illusion of a mysterious drive is retained or even heightened...." The

inventor's address is Bilthoven, Netherlands.

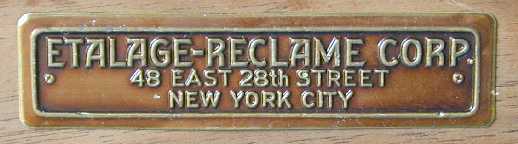

There is no model number or name indicated on this

clock. However, an advertisement refers to the clock as the Magic Crystal

Clock. A picture from the ad is shown at the right. The nameplate on the bottom

says Etalage-Reclame Corporation, 48 East

28th Street, New York City.

This is the same company that made clocks from earlier Prinz patents. The clock

could be thought of as an improved version of earlier designs and a connection

to the first Jefferson clock. A patent number RE 22640 is stamped in ink on

the bottom of the wood base. This is a reissue of patent number 2,248,195 on May 1, 1945.

There is no model number or name indicated on this

clock. However, an advertisement refers to the clock as the Magic Crystal

Clock. A picture from the ad is shown at the right. The nameplate on the bottom

says Etalage-Reclame Corporation, 48 East

28th Street, New York City.

This is the same company that made clocks from earlier Prinz patents. The clock

could be thought of as an improved version of earlier designs and a connection

to the first Jefferson clock. A patent number RE 22640 is stamped in ink on

the bottom of the wood base. This is a reissue of patent number 2,248,195 on May 1, 1945.

It is 9-7/8" high, 9-1/2" wide and 2-1/4" deep. Weight is 2 lbs. The lacquered solid walnut base is 7-1/2" wide, 2-1/4" high and 1-3/4" deep. The front and back of the wood is angled in at about 15 degrees. The sides are angled at 60 degrees. There are four 1/4" diameter brown felt pads on the bottom in the corners. The outer ring appears to be gold plated. It has rounded depressions about 1/16" deep and 1/4" in diameter to indicate the hours of 3, 6, 9 and 12 o'clock. The remaining hours have rounded depressions about 1/32" deep and 1/8" in diameter. A retaining ring holds the glass disk in the frame. Three small lugs are equally spaced around the rear of the frame. The retaining ring may be resiliently snapped into position to hold the disk.

The minute hand is located in front of the glass and

is attached to it by friction so that it can be easily turned to set to the

desired minutes. The hour hand and gear assembly is located behind the glass. A

shaft attached to the center of the glass has a gear on it that's in the counterweight

gear assembly. The counterweight always stays in a vertical location from

gravity. It provides a fixed position needed to drive other gears that advance

the hour hand as the glass turns.

The minute hand is located in front of the glass and

is attached to it by friction so that it can be easily turned to set to the

desired minutes. The hour hand and gear assembly is located behind the glass. A

shaft attached to the center of the glass has a gear on it that's in the counterweight

gear assembly. The counterweight always stays in a vertical location from

gravity. It provides a fixed position needed to drive other gears that advance

the hour hand as the glass turns.

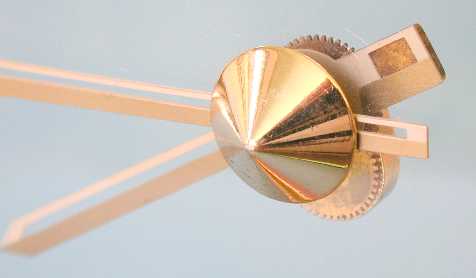

The picture shows the rear of the hands and the pear shaped

counterweight assembly. There's also a counterweight at the end of the hour

hand and can be seen near the top left of the picture. It serves to hold the

hour hand in proper position relative to the minute hand. The hour and minute

hands are about 3/16" wide. They have a slot about .038" wide for

most of their length. The wide portion is gold colored and the thinner portion

is light beige. The back of the hands is also light beige.

The picture shows the rear of the hands and the pear shaped

counterweight assembly. There's also a counterweight at the end of the hour

hand and can be seen near the top left of the picture. It serves to hold the

hour hand in proper position relative to the minute hand. The hour and minute

hands are about 3/16" wide. They have a slot about .038" wide for

most of their length. The wide portion is gold colored and the thinner portion

is light beige. The back of the hands is also light beige.

The clock is powered by a synchronous motor made by Haydon

Mfg. Co, Torrington, Conn. It's rated at 110V--60C and 2.3W. The output gear is

1 RPM.

A 60:1 reduction results in the clock face turning at the required 1/60 rpm, or

one revolution per hour. The motor is mounted in a metal housing 2-1/2"

wide and 2-1/4" high that extends into the wooden base. The assembly is

painted dark brown. The numbers 8/48 on the motor indicate that the motor was

made in August of 1948 and the clock may have also been made in 1948. A second

clock has been found with a motor date of December 1949.

The clock is powered by a synchronous motor made by Haydon

Mfg. Co, Torrington, Conn. It's rated at 110V--60C and 2.3W. The output gear is

1 RPM.

A 60:1 reduction results in the clock face turning at the required 1/60 rpm, or

one revolution per hour. The motor is mounted in a metal housing 2-1/2"

wide and 2-1/4" high that extends into the wooden base. The assembly is

painted dark brown. The numbers 8/48 on the motor indicate that the motor was

made in August of 1948 and the clock may have also been made in 1948. A second

clock has been found with a motor date of December 1949.

Jefferson made the first Golden Hour clock on December 2, 1949 after patent rights were purchased from Leendert Prins. The Jefferson Golden Hour and their later similar clocks are a redesign using the Prins patent. The original Prins design does tend to be a little tipsy as most of the weight is at the top and the base is not deep enough to keep it steady. In comparison, the Golden Hour is very stable and has no tendency to tip over.

One clock I have seen had an embossed label pasted on the bottom. Although the front part of the label had been peeled off the embossing could still be read. It says Tourneau, Importers of Watches, Madison Avenue, New York. This may have been the dealer that originally sold the clock back in the late 40's.

On the Inside

The square metal housing around the motor is made of

steel. It is held in place by four metal tabs. These must be bent in order to

get the housing off. In one clock I have seen the tabs broken off, probably

from repeated bending. The motor is mounted on a metal casting and is attached

to the base with three wood screws. The indent in the wood in the center is

where an intermediate gear fits. When the wood screws are removed the motor,

casting and ring assembly can be removed from the base.

The square metal housing around the motor is made of

steel. It is held in place by four metal tabs. These must be bent in order to

get the housing off. In one clock I have seen the tabs broken off, probably

from repeated bending. The motor is mounted on a metal casting and is attached

to the base with three wood screws. The indent in the wood in the center is

where an intermediate gear fits. When the wood screws are removed the motor,

casting and ring assembly can be removed from the base.

The two decorative brass balls are held with two

threaded pieces that have been inserted into the wood base. This is all in

accordance with the patent description. The two flat head machine screws that

hold the casting to the outer ring can be seen in the picture below and to the

right. The view is from the front of the clock.

The two decorative brass balls are held with two

threaded pieces that have been inserted into the wood base. This is all in

accordance with the patent description. The two flat head machine screws that

hold the casting to the outer ring can be seen in the picture below and to the

right. The view is from the front of the clock.

The motor output gear has 6 teeth and runs at 1 RPM. It meshes

with a brass intermediate gear that has 18 teeth and this makes a gear

reduction of 3 to 1.

The motor output gear has 6 teeth and runs at 1 RPM. It meshes

with a brass intermediate gear that has 18 teeth and this makes a gear

reduction of 3 to 1.

The intermediate gear meshes with the outer ring gear that has 360 teeth. This is a reduction of 20 to 1. The total reduction is 60 to 1 and the outer gear rotates at the required one revolution per hour.

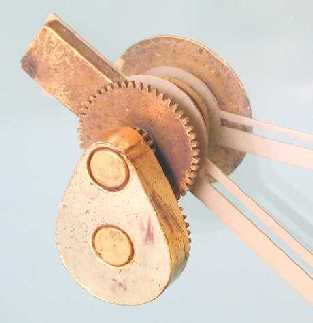

The picture at the left shows some of the parts of the

dial ring assembly spread apart. This view is from the rear. It consists of a

gold colored rear cover shown at the top. The rear cover is held in place by 3

small tabs that are part of the ring casting. Behind and below it is the outer

gear ring with the glass that is glued to it. The teeth of the outer ring are

triangular much like a saw blade. The ring is made of steel. Below that is the

cast ring showing several steps. The intermediate brass gear can just be seen

above the motor gearbox at the bottom of the picture.

The picture at the left shows some of the parts of the

dial ring assembly spread apart. This view is from the rear. It consists of a

gold colored rear cover shown at the top. The rear cover is held in place by 3

small tabs that are part of the ring casting. Behind and below it is the outer

gear ring with the glass that is glued to it. The teeth of the outer ring are

triangular much like a saw blade. The ring is made of steel. Below that is the

cast ring showing several steps. The intermediate brass gear can just be seen

above the motor gearbox at the bottom of the picture.

On either side of the intermediate gear, the ends of a circular split retainer ring can be seen. This circular retainer is shown the way it fits in one of the steps. It's made of brass wire that's 0.073" in diameter. It goes between the outer gear ring and the cover and serves to keep the outer gear ring and glass assembly in place.

Two raised areas are on the inside of the ring. This

is where the weight of the glass/hand assembly rests. The assembly weighs 191

grams or about 6.7 ounces. The wear is not equal for the two tabs indicating

that the retainer ring is probably not centering the gear ring from front to

back as well as it should have.

Two raised areas are on the inside of the ring. This

is where the weight of the glass/hand assembly rests. The assembly weighs 191

grams or about 6.7 ounces. The wear is not equal for the two tabs indicating

that the retainer ring is probably not centering the gear ring from front to

back as well as it should have.

![]()

Model 146. This was made by Sonic Industries, Inc., New York 13, NY.

The mystery here is that there appears to be no obvious way to make the hands

move. Unlike the Jefferson Golden Hour clock, there's not even a weight or

gears to drive the hour hand from the minute hand. The dial frame and back is

made of a cast brass. There are 12 countersunk circles 1/4" in diameter to

indicate the hours. The back plate is held in place by four screws in the

corners. The black base containing the motor is Bakelite. Three patent numbers

are indicated on the label. They are 2,248,195, 2,201,376 and 1,855,648. These

were awarded to Leendert Prins and are described in my Jefferson Electric

History page.

Model 146. This was made by Sonic Industries, Inc., New York 13, NY.

The mystery here is that there appears to be no obvious way to make the hands

move. Unlike the Jefferson Golden Hour clock, there's not even a weight or

gears to drive the hour hand from the minute hand. The dial frame and back is

made of a cast brass. There are 12 countersunk circles 1/4" in diameter to

indicate the hours. The back plate is held in place by four screws in the

corners. The black base containing the motor is Bakelite. Three patent numbers

are indicated on the label. They are 2,248,195, 2,201,376 and 1,855,648. These

were awarded to Leendert Prins and are described in my Jefferson Electric

History page.

On a shipping box it says "The Mystery Electric

Clock, Etalage, MagiClock, Daton Corp. New

York 11, N.Y." The motor is made

by Haydon and rated at 1/2 RPM. Power requirements are 115V 60C 2.5W. The clock is

8-1/2" high, 6-3/4" wide and 2-3/4" deep. The base height is

1-3/4". It is UL approved. Weight is 2.0 lbs.

On a shipping box it says "The Mystery Electric

Clock, Etalage, MagiClock, Daton Corp. New

York 11, N.Y." The motor is made

by Haydon and rated at 1/2 RPM. Power requirements are 115V 60C 2.5W. The clock is

8-1/2" high, 6-3/4" wide and 2-3/4" deep. The base height is

1-3/4". It is UL approved. Weight is 2.0 lbs.

The face consists of two transparent plastic discs 5-15/16"

diameter. They are concave shaped as seen from the outside. The front disc has

the minute hand attached by friction and a 3/8" diameter knob at the

center that can be used to set the minutes. The rear disc has the hour hand

attached in a similar way and with a similar knob to adjust the hours. This

method of setting the time is much easier than the method described in the

original Prins patent. Reduction gears in the base drive the two discs, one for

the hours and one for the minutes.

The face consists of two transparent plastic discs 5-15/16"

diameter. They are concave shaped as seen from the outside. The front disc has

the minute hand attached by friction and a 3/8" diameter knob at the

center that can be used to set the minutes. The rear disc has the hour hand

attached in a similar way and with a similar knob to adjust the hours. This

method of setting the time is much easier than the method described in the

original Prins patent. Reduction gears in the base drive the two discs, one for

the hours and one for the minutes.

The knobs don't show in the side view because they are

in the center of the concave discs.

The knobs don't show in the side view because they are

in the center of the concave discs.

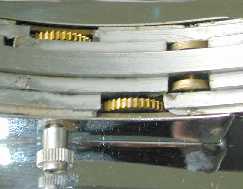

Two 6 tooth gears come through the base to drive the

separate plastic discs. One is near the front and the other is near the rear.

The gears turn at different speeds for the hour and minute hand. Each plastic

disc has 300 cogs that engage the respective gear. The minute hand can be seen

at the upper right in the gear photo. One disc has been removed to show the

gears. The cogs in the plastic discs show no sign of wear in any of the clocks

I have seen.

Two 6 tooth gears come through the base to drive the

separate plastic discs. One is near the front and the other is near the rear.

The gears turn at different speeds for the hour and minute hand. Each plastic

disc has 300 cogs that engage the respective gear. The minute hand can be seen

at the upper right in the gear photo. One disc has been removed to show the

gears. The cogs in the plastic discs show no sign of wear in any of the clocks

I have seen.

A 4" leaf type spring is attached to the front

plate In the picture it's located just behind the plastic disc at the bottom.

The spring pushes the disc against the closest gear so it makes good contact.

The right side of the spring is glued to the front frame and the left side is

free to slide when the disc is installed. A similar spring is glued to the back

plate and pushes the rear disc against the other gear. I have seen five of

these clocks and only two of them still have the springs. The others were

apparently lost. The clocks don't work very well without them.

A 4" leaf type spring is attached to the front

plate In the picture it's located just behind the plastic disc at the bottom.

The spring pushes the disc against the closest gear so it makes good contact.

The right side of the spring is glued to the front frame and the left side is

free to slide when the disc is installed. A similar spring is glued to the back

plate and pushes the rear disc against the other gear. I have seen five of

these clocks and only two of them still have the springs. The others were

apparently lost. The clocks don't work very well without them.

Because the springs have pushed the 6-tooth gears over

the years there has been an unusual amount of wear both in the brass gears and

the holes in the Bakelite base where the gears pass through. An accumulation of

Bakelite powder can be seen at the bottom of the picture that has worn from the

left hole in the base. Later versions avoided wear on the brass gears by using

steel instead.

Because the springs have pushed the 6-tooth gears over

the years there has been an unusual amount of wear both in the brass gears and

the holes in the Bakelite base where the gears pass through. An accumulation of

Bakelite powder can be seen at the bottom of the picture that has worn from the

left hole in the base. Later versions avoided wear on the brass gears by using

steel instead.

The motor is mounted on a metal plate and drives the

smaller minute gear. The other end drives the minute disc. This gear also

drives the large gear. The other end of the large gear drives the hour disc.

The center portion of the large gear is identical to the smaller gear. It is

force fitted into a hole in the large gear. I noticed it was soldered in place

as well in a couple of the clocks.

The motor is mounted on a metal plate and drives the

smaller minute gear. The other end drives the minute disc. This gear also

drives the large gear. The other end of the large gear drives the hour disc.

The center portion of the large gear is identical to the smaller gear. It is

force fitted into a hole in the large gear. I noticed it was soldered in place

as well in a couple of the clocks.

The brass gears had an additional problem. A small tip at the end of each gear fits into the metal plate that the motor is mounted on. In some clocks, these have worn off completely and of course the clocks no longer work properly. The steel tips have not been affected.

Another version of this clock has two lights mounted

in the rear of the base. The tops of the bare bulbs stick up from sockets

mounted inside the base. There's a switch at the left side in the back of the

base to turn the lights on and off. The two lamps are wired in parallel.

Another version of this clock has two lights mounted

in the rear of the base. The tops of the bare bulbs stick up from sockets

mounted inside the base. There's a switch at the left side in the back of the

base to turn the lights on and off. The two lamps are wired in parallel.

This clock has the same model number and is otherwise identical to the non-lighted version. So far, I have seen two of these. The lamps are type S-6 and have a candelabra base. They are rated at 6 watts and can still be found at electrical supply stores.

"Operating

Instructions and Warranty

Please Read Carefully

Before operating your Magi-Clock, the following instructions should be observed to prevent breakage. The piece of cardboard wedged between each transparent dial face and the black base to hold the dial faces rigid must be removed otherwise the clock will not operate and damage may result.

Instructions

To start clock insert plug to 115 volt AC outlet. To set hands turn gold plated buttons in center of dial. The front button controls the minute hand while the rear button controls the hour hand.

Care

To clean the front and rear discs use a small dab of absorbent cotton or soft flannel and wipe gently. Do not use harsh cloths or liquids as you may scratch the plastic and impair the appearance. We warrant each new clock to be free of defects, and agree to remedy any defect of materials or workmanship, or to furnish a new part within ninety (90) days after date of sale to original purchaser, provided the clock is returned to our factory transportation charges prepaid. This warranty does not apply to any clock that has been subject to misuse, neglect, accident, or use in violation of instructions furnished by us, or clocks repaired or altered outside our factory. This clock has been carefully tested and packed; should there be any damage, make immediate claim with the carrier"

![]()

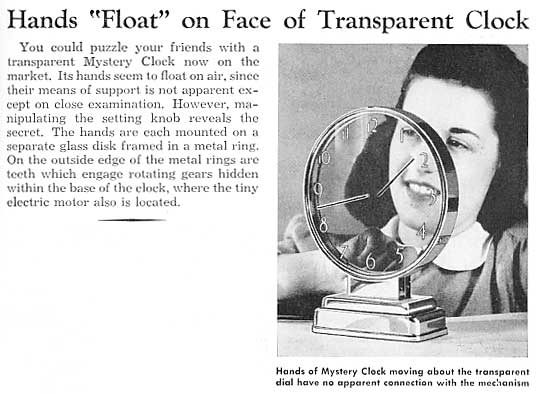

Etalage Transparent Mystery Clock (Earlier Patent)

This clock is similar to the Prins patent number

2,248,195. It was applied for on April 30, 1937 and issued on July 8, 1941. It was reissued May 1, 1945. Application for reissue was June 14, 1944 serial number 540,233. The patent describes a clock

with two transparent rotating discs, one for the minute hand, and one for the

hour hand. The geared perimeters are driven at different speeds from different

gears in a gear train driven by a motor. The two discs are enclosed by front

and back transparent discs. The clock differs from the patent in that the hour

and minute discs are of equal diameter.

This clock is similar to the Prins patent number

2,248,195. It was applied for on April 30, 1937 and issued on July 8, 1941. It was reissued May 1, 1945. Application for reissue was June 14, 1944 serial number 540,233. The patent describes a clock

with two transparent rotating discs, one for the minute hand, and one for the

hour hand. The geared perimeters are driven at different speeds from different

gears in a gear train driven by a motor. The two discs are enclosed by front

and back transparent discs. The clock differs from the patent in that the hour

and minute discs are of equal diameter.

In the clocks pictured at the left, there are four glass discs. The front one has beveled edges and has the numbers painted on the back of the glass. The second disc has the minute hand glued to it. The minute hand is solid metal 3" long and 3/32" square. The Third disc has the hour hand glued to it. The hour hand is solid metal 2-1/8" long and 3/32" square. The rear disc is clear and has a beveled edge. It's there for protection. Three clamps hold the front and back discs in place. They are located at 12, 4 and 8 o'clock and each is attached to a cast metal outer ring with two screws. The numbers 10, 11 and 12 on the front glass are styled with the 1 being shorter. The clocks were sold with either a chrome or gold finish. The numerals are the same color in both clocks. They are yellow with a dark blue outline.

The steel base plate is force fitted into place inside the base. It has a green felt pad in each corner that is 3/4" in diameter. The plate is stamped with Etalage Reclame Corp., New York. AM patents 2,248,195, 2,201,376 and 1,855,648. There is no model name or number.

The clock is 9-5/8" high. The dial is 7-3/8" in diameter and 1-3/16" thick. The base at the bottom is 5-5/8" wide and 2-3/4" deep. It weighs 1750 grams or about 3.8 lbs. It comes with a 5-foot 5-inch brown line cord that has a small molded white plug on the end.

The outer ring contains all four pieces of glass.

Here's a picture of the bottom portion of the ring. The time set knob is at the

rear of the clock and can be seen at the bottom left side of the picture. The

two inner discs are 6-7/6" in diameter and are each glued to an outer gear

ring that has 360 teeth. The teeth of the outer ring are triangular much like a

saw blade. The rings are made of steel. Each disc and ring weighs 163 grams or

about 5.8 ounces. The outer beveled pieces of glass are 7-5/32" in

diameter.

The outer ring contains all four pieces of glass.

Here's a picture of the bottom portion of the ring. The time set knob is at the

rear of the clock and can be seen at the bottom left side of the picture. The

two inner discs are 6-7/6" in diameter and are each glued to an outer gear

ring that has 360 teeth. The teeth of the outer ring are triangular much like a

saw blade. The rings are made of steel. Each disc and ring weighs 163 grams or

about 5.8 ounces. The outer beveled pieces of glass are 7-5/32" in

diameter.

Much of the weight rests on two free turning brass wheels shown at the right of the gears. Each ring is shaped so that the teeth engage the brass drive gears that each have 36 teeth. This makes a gear reduction of 10 to 1. The front gear (at the top of the picture) turns the minute hand disc at one revolution per hour. The rear gear turns the hour hand.

A Synchron motor is located in the base and is made by

the Hansen Mfg. Co., Inc, Princeton, Indiana. It is model 600, 4 rpm, 110V, 60C. The gears in the

picture are located in the neck of the clock. The view is from the bottom with

the motor removed. These gears reduce the rotation of the motor shaft from 4

rpm down to 1/6 rpm for the minute hand gear. They further reduce the rotation

for the hour hand gear to 1/72 rpm. Combined with the 10 to 1 reductions to the

minute and hour discs, this provides the required 1/60 rpm for minutes and

1/720 rpm for the hours.

A Synchron motor is located in the base and is made by

the Hansen Mfg. Co., Inc, Princeton, Indiana. It is model 600, 4 rpm, 110V, 60C. The gears in the

picture are located in the neck of the clock. The view is from the bottom with

the motor removed. These gears reduce the rotation of the motor shaft from 4

rpm down to 1/6 rpm for the minute hand gear. They further reduce the rotation

for the hour hand gear to 1/72 rpm. Combined with the 10 to 1 reductions to the

minute and hour discs, this provides the required 1/60 rpm for minutes and

1/720 rpm for the hours.

A worm gear on the shaft of the motor drives the upper left gear in the picture. A spring can be seen just below this gear. A smaller shaft for the time set knob goes through the spring to the 2-piece gear at the bottom left. The spring provides a friction clutch coupling from the motor to the 2-piece gear at the bottom left. The larger portion drives the minute hand disc. The smaller portion drives reduction gears to the hour hand. The hour drive gear is the large gear at the top of the picture. At the right of the picture are the two free turning brass wheels.

The set time knob can be turned in either direction. This will advance the minutes forward or backward. There is no separate advance for the hours and many turns may be needed to set the correct time.

This

clock is shown in the June 1942 issue of Popular Mechanics, page 61.

In the "Where-To-Buy-It Index" in this magazine on page 4A, it is

titled

"Transparent Mystery Clock… Etalage Reclame Corp., 48 E. 28th St.,

New York City"

![]()

This clock also follows the Prins patent number

2,248,195. It was reissued as RE22640 on May 1, 1945.

This clock also follows the Prins patent number

2,248,195. It was reissued as RE22640 on May 1, 1945.

The model number is 5-A. It appears to be identical to the Boots Boy model 5-A that was made by the Monitor Equipment Corporation. The only difference is the wording on the bottom plate. In fact, the clock may have been made for Rex Cole by Monitor. Like the Etalage model above, it has 4 glass discs enclosed by a metal hoop. The front and back discs are beveled for about 1/8" at the rim and are held by the hoop. The two inside discs are free to turn.

The numerals are on the back of the front piece of

glass. The minute hand is on the front of the second piece and the hour hand is

on the third piece. The fourth, or rear piece, is for protection. A running

"Boots Boy" figure is on the rear of the front glass just above the

6.

The numerals are on the back of the front piece of

glass. The minute hand is on the front of the second piece and the hour hand is

on the third piece. The fourth, or rear piece, is for protection. A running

"Boots Boy" figure is on the rear of the front glass just above the

6.

The metal hoop appears to be chrome plated and is held

to a Y shaped post by two screws underneath. The rear of the post has a

1/2" knurled knob to set the time. The two screws in the picture hold the

dial assembly to the base of the clock. To set the time, the knob can be turned

in either direction. This will advance the minutes. There is no separate

advance for the hours and many turns may be needed to set the correct time.

The metal hoop appears to be chrome plated and is held

to a Y shaped post by two screws underneath. The rear of the post has a

1/2" knurled knob to set the time. The two screws in the picture hold the

dial assembly to the base of the clock. To set the time, the knob can be turned

in either direction. This will advance the minutes. There is no separate

advance for the hours and many turns may be needed to set the correct time.

The base is a smooth brown wood grain Bakelite. It is 6" wide, 2-5/8" deep at the center and 1-5/8" high. The hoop is 5-3/16" in diameter. The overall height is 7-1/2" including the four rubber feet on the base. The clock weighs 640 grams or about 1.4 lbs.

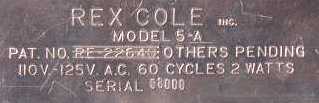

The nameplate says "REX COLE Inc., Model 5-A Pat.

No. RE 22640 others pending, 110V - 125V A.C. 60 cycles 2 watts serial

08000." The RE 22640 has three lines drawn through it. An earlier clock,

serial 03145, does not have the three lines through it. This is the same patent

number found on the Etalage Mystery Clock.

The nameplate says "REX COLE Inc., Model 5-A Pat.

No. RE 22640 others pending, 110V - 125V A.C. 60 cycles 2 watts serial

08000." The RE 22640 has three lines drawn through it. An earlier clock,

serial 03145, does not have the three lines through it. This is the same patent

number found on the Etalage Mystery Clock.

Although self-starting, the motor looks like an early

design. The wheel in the center is on the rotor shaft. The coil is in the rear.

The laminations are attached with two screws to the bottom casting, which is

possibly made of zinc. The laminations are 2" wide and 1-5/8" deep

Although self-starting, the motor looks like an early

design. The wheel in the center is on the rotor shaft. The coil is in the rear.

The laminations are attached with two screws to the bottom casting, which is

possibly made of zinc. The laminations are 2" wide and 1-5/8" deep

The output from the motor is a tiny 1/8" gear with 10 teeth. This drives a thin 5/8" gear having 60 teeth. The shaft of the 60-tooth gear goes through a metal plate into the Y shaped post.

The Boots Boy Emblem and Rex Cole

A book titled Rex Cole on Salesmanship by Rex Cole in collaboration with C. D. Frazer was published by B. C. Forbes Publishing Company, 120 Fifth Avenue, New York City in 1935 (253 pages). It's a guide on how to be a good salesman. "It is based principally upon the experience of Rex Cole and members of his organization." In the introduction it states:

"On the hood of his car and at his farm, on the

chinaware, the table linen, the door mats, the flag pole and every other nearly

appropriate place, he has neatly affixed his emblem--The Seven League Boots

Boy. Remember the legend? The boy whose boots helped him step clear over all

obstacles, over depressions, from mountain to mountain, seven leagues at a

time--toward his objective. Here is a silent sermon for salesmen who falter

along on the ground and do not see high or far enough. This is one of the first

lessons: "Hitch your wagon to a star"; or better still, as Justice

Holmes suggested, steer your course by a star that you have never seen."

"On the hood of his car and at his farm, on the

chinaware, the table linen, the door mats, the flag pole and every other nearly

appropriate place, he has neatly affixed his emblem--The Seven League Boots

Boy. Remember the legend? The boy whose boots helped him step clear over all

obstacles, over depressions, from mountain to mountain, seven leagues at a

time--toward his objective. Here is a silent sermon for salesmen who falter

along on the ground and do not see high or far enough. This is one of the first

lessons: "Hitch your wagon to a star"; or better still, as Justice

Holmes suggested, steer your course by a star that you have never seen."

This emblem came from a washing machine made by the Monitor Equipment Corporation. Monitor also made several different AM radios in the 1940's.

Rex Cole Inc. was the New York distributor for General Electric refrigerators. Remember the ones that had the cylindrical compressor on the top? Starting in 1928, Raymond Hood designed four Rex Cole showroom buildings. They were all different but had a modernist approach typical of the period of "stylistic ferment." An article about the buildings was published in American Architect, December 1931. The buildings were located at 6528-6530 Fourth Ave., Bay Ridge, Brooklyn, 2392 Grand Concourse in The Bronx, 137-155 Northern Blvd in Flushing, Queens and at the gateway to the Ridge section of Brooklyn. One building had a very large GE symbol etched into the transparent glass so that at night, when lit from behind, the facade became a glowing advertisement. Another building had a large replica of the GE refigerator at the top.

![]()

A Boots Boy clock is shown at the left and appears to

be identical to the Rex Cole except for the wording on the bottom plate. It's

made by the Monitor Equipment Corporation. The Boots Boy figure is just above

the 6 as in the Rex Cole.

A Boots Boy clock is shown at the left and appears to

be identical to the Rex Cole except for the wording on the bottom plate. It's

made by the Monitor Equipment Corporation. The Boots Boy figure is just above

the 6 as in the Rex Cole.

The bottom plate shows the Boots Boy figure and name .

The four felt feet are also visible.

The bottom plate shows the Boots Boy figure and name .

The four felt feet are also visible.

![]()

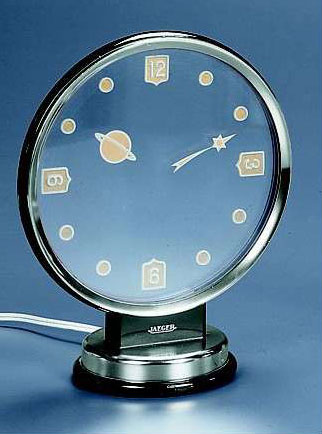

LeCoultre Mystery Clocks

Signed by Jeager LeCoultre. Dated about 1940. Two

inner glass discs rotate driven by a motor and gears in the base. The hours are

indicated by a planet and minutes are indicated by a shooting star. A

stationary front glass has stars indicating the hours. The outer ring, base and

ball feet are chrome plated.

Signed by Jeager LeCoultre. Dated about 1940. Two

inner glass discs rotate driven by a motor and gears in the base. The hours are

indicated by a planet and minutes are indicated by a shooting star. A

stationary front glass has stars indicating the hours. The outer ring, base and

ball feet are chrome plated.

This clock is very similar to the Etalage transparent mystery clock described above and was apparently made about the same time. This design is also based on a patent awarded to Leendret prins.

It may have been made by Etalage for LeCoultre.

In addition, Jaeger LeCoultre also sold another version having a different base. Circles are used to indicate the hours instead of stars. Very little is known about these clocks and where they fit in with licensing with Leendert Prins.

![]()

|

|

|

![]()

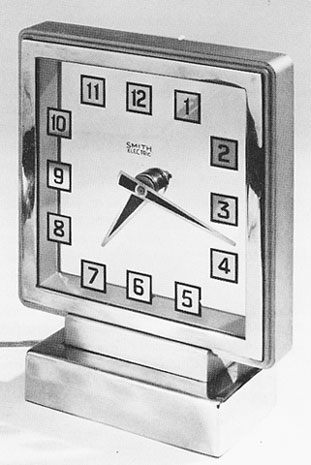

Another mystery is the relationship between Smiths and Jaeger. Here, the clocks seem to be identical except for the name and paint on the hands. Although the name Jaeger appears on the dial glass, the bottom plate says “Made in England.” This indicates that the clock was made by Smiths and sold by Jaeger with their name on it.

|

|

|

|

Smith Electric |

Jaeger Electrique |

|

|

|

|

Jaeger Time Adjust Knob |

Jaeger Bottom Plate |

This clock was patented in 1934. The principle method of operation may predate the Mastercrafters Fantasy clock. There are three pieces of glass. The front piece has the numerals. The rear plate has a hole in the center with a pin that supports the center glass and the hand assembly. The center glass moves imperceptibly slowly to advance the hands and is driven through a roller arm and motor in the base. The finish is nickel.

![]()

2,201,376

This was filed on March 8, 1938, and issued May 21, 1940. It concerns a method of projecting an enlarged image of the clock hands and numerals on a wall or ceiling. The inventor's address is Flushing, New York.

![]()

1,855,648

This was filed on June 29, 1931 and issued on April 26, 1932. It concerns an advertising device that has an eccentrically placed arm fastened to a transparent disc that held the advertising article. The rotating transparent disc was driven by the edge, which was hidden from sight.

Other Clock Pages I Have Created

|

A history of the Jefferson Electric Company including many mystery clocks and other products. Lots of pictures and text. |

|

|

A history of the Mastercrafters Clock and Radio Company. Includes pictures and descriptions of some of their clocks including a mystery clock. |

|

|

A major Chicago competitor to Jefferson that made similar mystery clocks and also animated clocks. |

|

|

Includes very early and late clocks from companies other than those already listed. |

|

|

Also known as projection clocks. A history of these interesting clocks from 1909 to present. |

|

Other pages I have created and personal information. |

|

|

Sorry, I don't know the present value of these clocks. |

More text and pictures about Mastercrafters will be added as my research continues. Any comments, corrections, or additions are welcome. |

|

Email

to |

All

contents are copyright 1998-2005 |