The NoTone Loudspeaker System

By Roger Russell

These pages are copyrighted.

No portion of this site may be reproduced in whole or in part

without written permission of the author.

NoTone is a new kind of Acoustics Company that is dedicated to the pursuit of better sound reproduction. NoTone employs engineers and scientists from many different fields to pool their knowledge of chemistry, physics, biology, electronics and other disciplines. The company began operations in 1998 as an exclusive research foundation. However, an accident in the laboratory turned out to be a positive creation. One of the first applications was the Model IV Loudspeaker System.

The Model IV is truly an engineering marvel. Thanks to the visionary concepts of Dr. Verity, the new technology has been used to pave the way for the most outstanding sound ever heard by human beings on this planet, and maybe other worlds as well. This system presents ideal listening for dummies as well as professionals and has been recommended by the National Board of Listening Enthusiasts for its unbelievable performance. Countless listening panels have been assembled to establish these irrefutable results. It can be easily seen that the system will revolutionize the entire speaker industry in a very short time. Licensing is available for the applicable patents.

Care has been taken at every step of design and construction to bring not only the finest quality of sound but also a striking appearance that is acceptable in every home. Engineers have spent countless hours extracting every tiny bit of information that can be offered by the spectrum of elements available in our earth.

Acoustic material is made using the finest lint

collected from gas fired dryers located in prestigious neighborhoods. The lint

is deposited in collectors in the dryers and is almost at the correct density

by the time it is collected. By special arrangement with laundromat

managers and homeowners, we are allowed to be the sole collectors of this

unusually viable material. The amount of lint used in each system is determined

by weight. Acoustic measurements have been made to arrive at the exact amount

for each system to insure the best performance.

Acoustic material is made using the finest lint

collected from gas fired dryers located in prestigious neighborhoods. The lint

is deposited in collectors in the dryers and is almost at the correct density

by the time it is collected. By special arrangement with laundromat

managers and homeowners, we are allowed to be the sole collectors of this

unusually viable material. The amount of lint used in each system is determined

by weight. Acoustic measurements have been made to arrive at the exact amount

for each system to insure the best performance.

The cone material is made from wood pulp derived from the Sweet Daphne tree found only in Japan. This fibrous material is famous for its resistance to humidity and temperature changes and reduces cone distortion by a factor of 11.5. Further, it is relatively inexpensive to mold cones from the patented and proprietary slurry in a process known in the paper industry as “felting”. This material was once used by a well known manufacturing company in Japan but was discontinued due to the Daphne blight. However, the orchards are once again flourishing and blooming (shown at the right). Production of this rare fiber is now available exclusively for our use.

The voice coils are wound using a revolutionary

invention of silver plated silk. It is known that silk can be extracted from

the silk moth cocoon in a single strand. We take advantage of this unique

natural material and, through our patented process, plate the silk with a low

resistance layer of oxygen free silver. The light weight coil provides response

so fast that special high speed test equipment had to be designed to measure

it.

The voice coils are wound using a revolutionary

invention of silver plated silk. It is known that silk can be extracted from

the silk moth cocoon in a single strand. We take advantage of this unique

natural material and, through our patented process, plate the silk with a low

resistance layer of oxygen free silver. The light weight coil provides response

so fast that special high speed test equipment had to be designed to measure

it.

In addition, because the silver is deposited only on the outside of the silk, the electrons travel only on the outside and enable response to be extended not only in the highest audible range but also into the ultrasonic range.

Studies have shown that the sound generated by such a unique wire combined with a patented magnet structure improves the fidelity to a degree never before achieved by any other speaker manufacturer.

The magnets are made using barium ferrite mixed with uranium oxide and formed by the sintering process. Use of uranium in glassware such as dinner plates, butter dishes, etc. was discontinued in the 1940’s, perhaps because of the health advantages it offered. It killed all the germs in food and was a threat to the medical profession, reducing the number of visits to the doctor.

As in conventional speakers, the magnetic flux can be concentrated in the magnetic gap by use of a steel magnetic structure. However, as in the glassware, definite advantages of uranium are realized. Radiation from the magnet is also concentrated in the gap and acts a scrubber for all impurities generated by the equipment used to drive the speakers as well as in the recordings themselves. This is all accomplished at an atomic level. The impurities, such as distortion and coloration, pass through the relatively transparent silk/silver wire and are totally and completely disintegrated leaving only the pure living undistorted sound.

The action is accomplished by electrons, neutrons and

protons trapped in the magnetic field. The behavior is much the same as in the

giant cyclotron used to study atomic phenomena at the Fermi Laboratory in

Illinois, but on a much smaller scale. This is accomplished by applying

magnetization only at specific locations around the perimeter of the magnet.

The magnetic fields are conducted to the gap by special grain-oriented steel

“fingers”. The “hot spots” that are created provide a series of alternating north

and south poles. Particles entering this complex field are kicked up to a

higher energy level each time they pass through one of the polar reversals.

Final velocity is determined by the strength of the fields and approaches about

half of the speed of light—fast enough for the scrubbing action to be

inaudible. A portion of the reversal pole pieces is shown at the left.

The action is accomplished by electrons, neutrons and

protons trapped in the magnetic field. The behavior is much the same as in the

giant cyclotron used to study atomic phenomena at the Fermi Laboratory in

Illinois, but on a much smaller scale. This is accomplished by applying

magnetization only at specific locations around the perimeter of the magnet.

The magnetic fields are conducted to the gap by special grain-oriented steel

“fingers”. The “hot spots” that are created provide a series of alternating north

and south poles. Particles entering this complex field are kicked up to a

higher energy level each time they pass through one of the polar reversals.

Final velocity is determined by the strength of the fields and approaches about

half of the speed of light—fast enough for the scrubbing action to be

inaudible. A portion of the reversal pole pieces is shown at the left.

The magnets are completely shielded so they will not glow in the dark and not disturb any listening pleasure. It should be noted that the half life of uranium is 1.2 billion years and therefore there is no significant problem of deterioration. You will be able to hand down the systems from generation to generation and still have the same exceptional performance.

The NoTone Model IV Studio Standard Reference Monitor System

Balrog Award Winner 2003

|

|

Here is the production cabinet for the Model IV. The styling has been created to represent something that is familiar in the home and can be used in any room. Thanks to independent surveys, the appearance has been found to be unanimously acceptable.

The upper panel is for tweeters and mid-ranges. The lower panel is for the woofers.

The system is shown with the panels in place. A particular accent has been incorporated into the woofer panel to add interest to this fascinating work of art. Care has been taken to preserve symmetry on the left and right sides.

The panels have been designed to open, in the unlikely event that access to the drivers is needed.

The system is available in a choice of custom colors or genuine veneers that are simulated. |

The Model IV is also a familiar sight in most recording studios. It has proven to be an absolute necessity for almost every recording engineer and is also enjoyed by visitors. What's more, it comes in handy for late night parties, either in the studio or at home and provides really cool sound. In order to handle exceptional peak demands, the Model IV has a built-in compressor that automatically turns on to cool the driver coils.

The Model IV has been nominated by the Granny Awards Committee to be the finest system and has been selected best in show by the AKC. The system is under complete warranty, including parts and labor, for the life of the product.

NoTone Acoustics, Ltd., 666 Triffid Farm Road, Altamonte Springs, Florida 32701

Visit our new NoTone factory and showroom located in the Research Quadrangle in Altamonte Springs. In our demonstrations, we use an exclusive 257 bit recording of the dynamic sounds from Beethoven’s Wellington’s Victory.

Our car installation facility is temporarily unavailable. Due to the high sound level demands by our customers, there were some unexpected stresses placed on the structure when testing the Model IV system mounted on the back of a customer’s Ford 150 pickup truck. The 50 Hz sound level exceeded his expectations of 180 dBA. Fortunately, minimum damage was received by the Model IV.

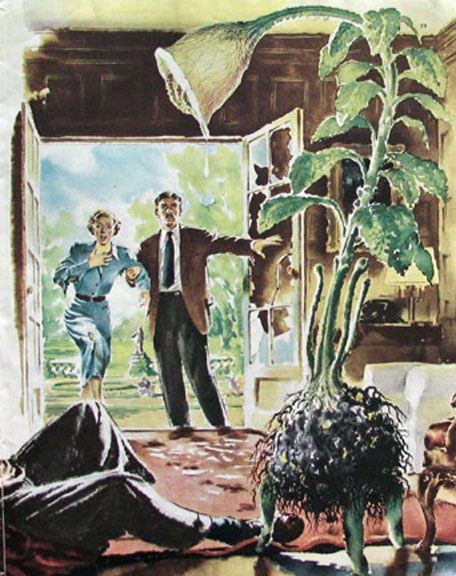

Customer service is located at the side entrance to the factory. We feel that the integration of local flora with the building makes a more environmentally friendly décor. The landscaping was provided by Nematode Shrubberies Incorporated. In the unlikely event that you may need assistance, the door is always open and our friendly assistants are waiting for you in our experimental laboratory.

1. The Inaudibility of Distortion Provided by Radioactive Magnets. By Max E. Well, DDS.

2. Silk Voice Coils, A New Approach by Dr. Uno Turna, Presented at the Audio Forum, New York City , August 2001

3. Patent No. 8,023,769 Unbelievable System awarded to Dr. Lia R. Verity

4. Patent No. 8,327,060 Low Power Cyclotron awarded to Victor Olas, PHD

5. Patent No. 8,539,145 Daphne Paper Process awarded to Iva Blender, BS, MS, and PHD

Our staff has recently had another accident in the lab and once again a new concept has been achieved. The new system is at the cutting edge of electrical and chemical technology and is unlike any system ever devised. However, the design will not be completed until late this year.

A young Triffid plant was recently discovered on the main building property. The top stem of this youngster was dispatched quickly before the deadly blossom had formed. The photo at the left shows the main stem that had been cut with a rotating disc using an anti-Triffid crossbow. One of the main root stalks can be seen at the base that was cut during removal. The Triffid had apparently escaped from the farm down the road and maneuvered onto our property. It had established itself in a hiding place behind the main building apparently hoping to grow to maturity before attacking customers and employees. Please be reassured that a thorough search has been made of the premises and beyond and no other Triffids have been found. Needless to say a complaint has been registered with the farm and they have assured us that no further occurrences will be allowed.

|

|

|

The right-hand picture is a dramatization of how a fully grown Triffid can terrorize and kill humans. Triffids are known to grow very rapidly. They develop three main stalks that enable them to uproot themselves and move around on the ground, although somewhat awkwardly. The name Triffid is derived from the three or tri-arrangement of root stalks. A mature plant develops a single large blossom. Inside the blossom is a coiled whorl with a poison-tipped stinger. This can rapidly whip out for a surprisingly long distance to stun and kill victims. The plant then remains in the area for the body to decay and furnish nutrients in the soil.

Since it has no eyes, it relies on sound and vibration for detection of prey. The plants have a rudimentary communication system. The short growths at the base of the stem can move against each other with a rattling sound that is apparently picked up by other Triffids and could mean it has found a source of food or some such thing. The green growth at the base of the young Triffid in the photo would have eventually formed into those noisemakers. The complete potential of the sounds is not yet understood by scientists. Fortunately these carnivorous plants can be apprehended fairly easily. However, if you proceed unaware of such a danger, such as turning the corner of a building where a Triffid might be lurking, you can be struck before you know it.

Triffids are bred in special protected farms and are harvested for the fibrous stem material and, when processed, provides exceptionally good acoustic properties and is used for sound absorbing treatment in homes and factories. The poison, when greatly diluted, is useful for immunity treatment in homeopathic hospitals. The roots and leaves are ground up and spread inside the perimeter of the fences of the farms to deter migration. Previously, Triffids were known to group together and push against the fences in an effort to knock them down and escape.

|

About This Site |

||

|

|

More text and pictures will be added as my research on this speaker continues. Any comments are welcome. |

|

|

|

|

Created

by Roger Russell |